Tank Truck Sealed Parcel System

Safe and Controlled Fuel Delivery

SECU TECH's Secu Tank Control System offers an effective solution to the main problem oil companies and tank trucks face, concerning both accuracy in fuel quantities loaded and delivered, as well as fuel quality.

SECU Truck Control is a stand-alone Sealed Parcel Delivery (SPD) System, which provides monitoring and control of 64+4 critical points (inputs), and 40+2 outputs, so as to protect users against any tampering or manipulation attempt.

Furthermore, SECU Truck Control provides up to 16 analog inputs and up to 8 analog outputs, which can be used in the future for fuel level control or pressure control.

SECU Truck Control has modular, and can be used in both EX- and non-EX zones.

System Equipment

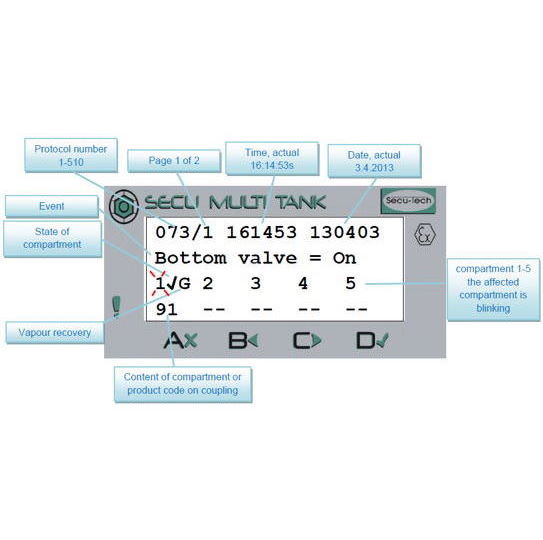

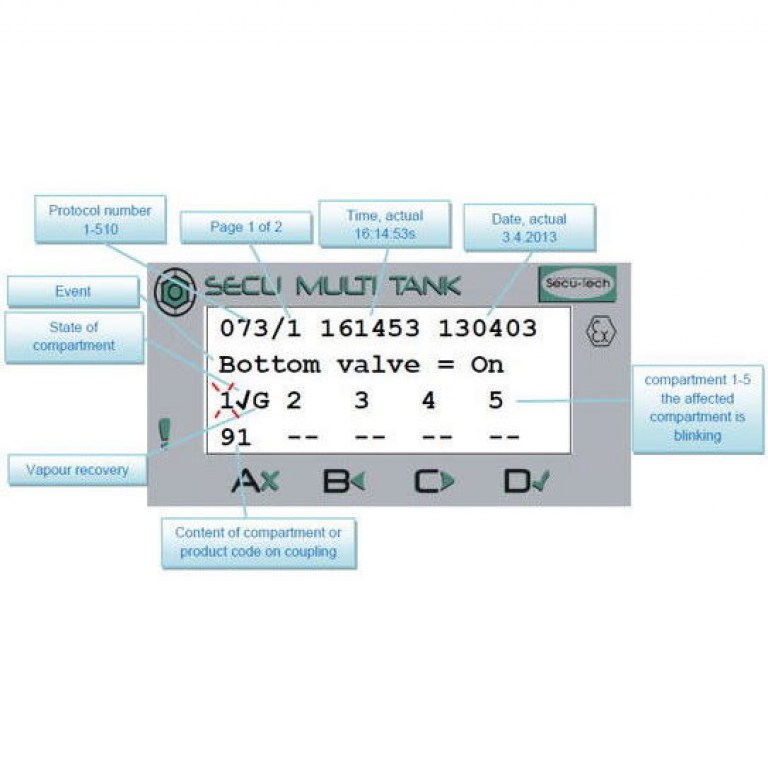

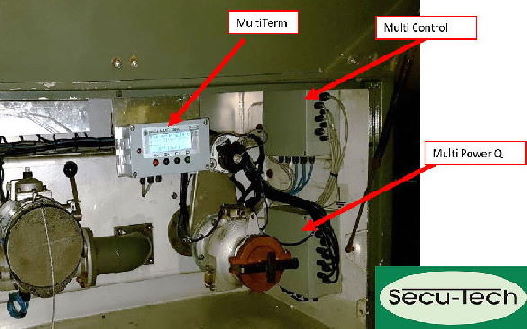

SECU MultiTerm

SECU MultiTerm (Display and Configuration Unit) provides information for operating conditions, as well as configuration of SPD System. It is the core of the system, providing data for all functions, displaying massages and alarms, and enabling system configuration. All procedures at the tank truck are logged with the exact activity and time. System administrator may define special configuration for special cases of tank trucks, fuel loadings and deliveries, as well as additional safety clauses. The display on the SECU MultiTerm is very easy to read, even from larger distances and with bad lighting conditions. Furthermore, the 4 buttons are easy-to-use even with work protection gloves.

SECU MultiPower gives an intrinsically safe supply to all components of the SECU MultiTank systems installed at the tank truck. The SECU MultiPower makes the grounding connections over the 12-pin plug and supervises them permanently. It isn´t possible to load or unload fuel, if the grounding is disconnected. Up to 20 different magnetic valves can be controlled with the SECU MultiPower at the tank truck, in EX “d” or EX “m” Zones. The SECU MultiPower is normally installed in the meter cabinet of the tank truck, and is certified according to EX Zone 1. The intrinsically safe supply of the tank truck devices ensures a high degree of safety, while its robust, weatherproof housing (IP 66) is appropriate for the hard daily use. All devices of the SECU MultiTank system communicate over a two-wire Modbus. Interfaces outward e.g. to tank truck electronics are possible through RS232 and RS485.

SECU Multi Control

SECU Multi Control supervises residue sensors (and other safety contacts), as well as the product channels. It can supervise up to 24 residue sensors. Through the SECU MultiRetain module can also monitor different control devices e.g. cover open contacts. All procedures are logged with the exact time. Product lines are monitored according to EN 14116 και EN 13616. Over the SECU MultiRetain modules can be assigned 6 and/or 12 product- or vapour connections. The SECU MultiControl is normally installed in the armature cabinet of the tank truck and is certified according to EX Zone 1. The intrinsically safe supply of the tank truck devices ensures a high degree of safety, while its robust, weatherproof housing (IP 66) is appropriate for the hard daily use.

SECU Valve Box

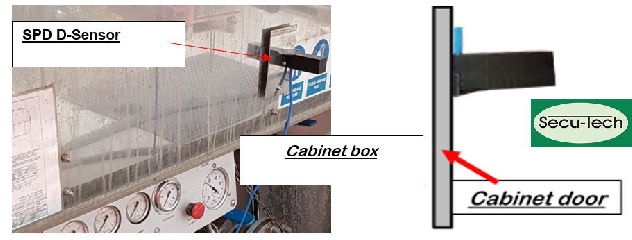

SECU Valve Box provides monitoring and status control of all tank truck's valves. SECU ValveBox is a closed and sealable control box to avoid and detect manipulations on tanker trucks. SECU ValveBox is available for 4 or 6 connections. It is a compact valve block and includes a central air supply, 3/2 ways solenoid valves including a safety cap and pressure switches as well as an electronic circuit within a terminal block. The electronic circuit of the SECU ValveBox supplies the status of the pressure switches via NAMUR signal to the control system from the tanker truck.

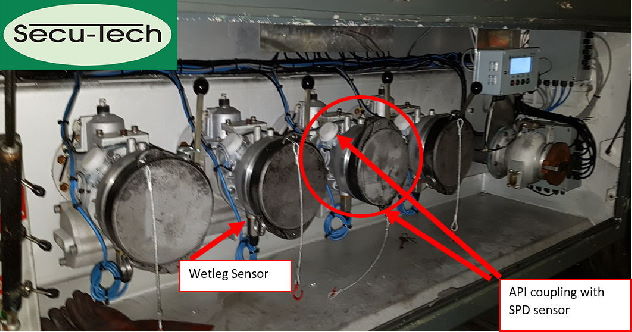

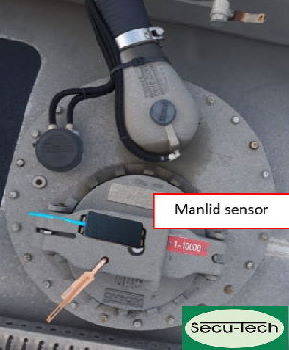

Sensors

The System is equipped with a wide range of special sensors, for both smooth and efficient operation, and connection and interface with other systems and applications. For example, tilt manlid sensors can be provided, to recognize closed or open position, and can be used in any type opening hatch. Namur signal output, for tampering and manipulation recognition. Other tilt door sensors are also available, with special locking device. For API Couplings, Wet-Leg-Sensors are available, as well as Proximity Sensors. The SECU Valve Box (see above) with Namur signal, which has pressure switches and bottom valves, as well as magnetic valves, protecting against any manipulation attempt. All lines are protected by copper pipes, for safety reasons and for avoiding system interferences.

Seals

Based on SECU-TECH's long experience in Sealed Parcel Delivery Systems, with numerous SECU MultiTank installations, a wide range of special seals has been developed, suitable for use in tank trucks, which are capable to avoid tampering or manipulation.

SECU Tube Seal is used to seal the compressed air pipe connections. The pipe connection (e.g. at the bottom valve) is surrounded with the plastic part and locked with a pin. The seal can only be opened by destroying it. For extra safery and protection, you can also use a numbered SECU Mechanical Seal (see below). SECU Retain Seal is used to seal the SECU wet-leg (retain) sensors. The cable of the sensor is pulled through the large sleeve until the sleeve is up against the API. Then attach the supplied washer to fix the cover with the two cable ties. SECU Mechanical Seal is a numbered seal that is recorded in a “number management file”. It is recommended to use this seal for all SECU MultiTank parts and in combination with the SECU Tube Seal and SECU Retain Seal.

Certifications & Standards

Secu-Tech is fully ISO 9001 and 14001 certified and ATEX-ISO production certified. All Secu-Tech products are manufactured in Austria and are ATEX certified.