From early 2015 our company designed, developed and certified a series of AdBlue Solutions (Dispensers and Container Units).

We manufacture since 2016 in Greece AdBlue Dispensers, certified according to ATEX and MID directives, which are exported to many European Countries.

Our AdBlue Container Units are provided in different capacities since 2017, offering a wide range of configuration, according to our customers' needs.

AdBlue Container Unit

The basic features of our AdBlue Container unit are:

- Above-ground container with 1.500, 2.000, 3.000, 4.000, 5.000, 6.000, 8.000, 10.000lt capacities, made of polyurethane (PU) panels

- Hatch-opening roof, for accessing tanks

- Side-door with lock, for accessing remote filling point, control panel, and maintenance

- AdBlue tanks with available capacities 1.500, 2.000, 3.000, 4.000, 5.000, 6.000, 8.000, 10.000lt, from polyethylene, suitable for AdBlue, according to ISO 22241

- Submersible pump with a capacity of 40lpm at the dispenser

- Stainless steel 316, 2’’ hydraulic installations

- Remote filling point 2’’, inside the container, dry break coupling, BSP, Viton seal (access through side-door)

- Master Control Panel (230V) inside the container

- Ventilation

- Heaters (optional feature, for areas with low temperatures)

- Electronic fuel level indicator

- Electronic HIGH & LOW LEVEL ALARM (optional feature)

- Probe sensor (optional feature)

All systems and equipment are installed inside the container unit (single-skin AdBlue tank, submersible pump, hydraulic installations, master control panel, remote filling point, high-level alarm, level indicator, heaters, ventilation, etc.

ADBLUE Dispensers Series

Our AdBlue Dispenser Series (pressure type) offers to our customers Single Dispensers, Double Dispensers, as well as Combi AdBlue-Petroleum Products Dispensers, manufactures in Greece by Dem. G. Spyrides S.A.

They are ΑΤΕΧ and MID certified, while bearing CE marking.

Provided with back-light LED displays, with 34mm digits.

For connection with Forecourt Control Systems, IFSF communication protocol is available.

MetersControl's (MC's) Positive Displacement Flow Meters offer the most suitable solution for tank truck applications, for accurate and reliable results.

Their robust housing offers protection against vibrations, for smooth operation under any transfer conditions.

MC's PD Flow Meters have a wide range of applications like gazoline, diesel, LPG, JET-A1 Fuel, kerosene, biodiesel, mazout, engine oils, various chemicals, solvents, acids, various industrial liquids, water.

Depending on the customer requirements, a wide range of accessories can be offered:

- Veeder Root Mechanical Registers

- Mechanical Printer

- Mechanical Register with Volume Preset

- Pulser for connection with Fleet Management Systems

Also, they can be provided with EMR3 Veeder Root Electronic Register, with additional features like:

- Temperature Compensation

- Data collection, registration and backup

- Wireless data transmission

- Connection with Fleet Management Systems

- Connection with Forecourt Management Systems and POS

MC's PD Flow Meters are characterized by their high quality, since they are designed and engineered in European Unity, and reliability, as they are certified according to:

- ATEX Directive 2014/34/EU, for use in potentially explosive atmospheres

- MID (OIML) Directive 2014/32/EU for measuring instruments

Spyrides Group provides constant availability for spare parts and accessories, covering all customers' requests and needs immediately.

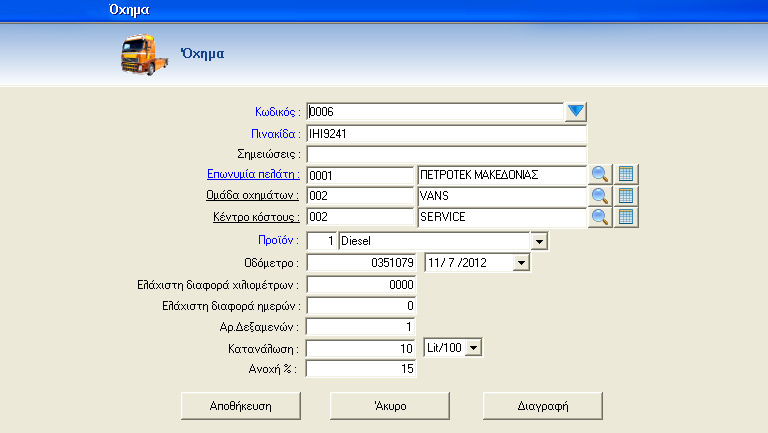

Building or Renovating an Internal (Industrial) Refuelling Site

By using an Internal (Industrial) Site for your Fleet of Vehicles (Transportation Companies, Quarries, Industrial Companies, Construction Companies, Public Sector etc.) you have immediate measurable benefits.

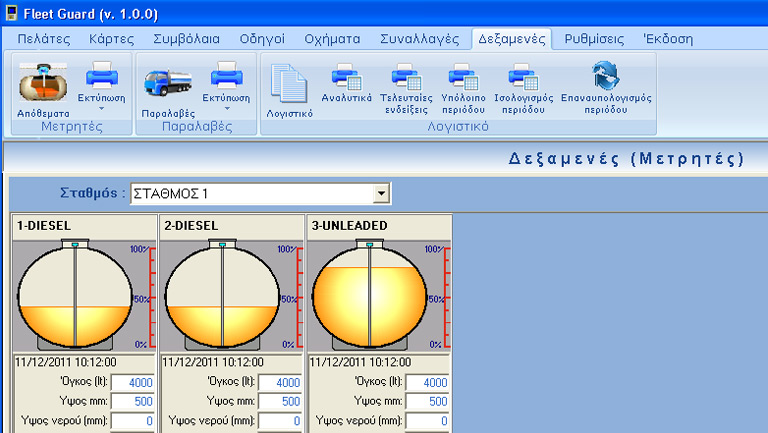

Our Fleet Management Systems enable you to have:

- Savings in fuel costs, since you purchase fuel directly from Petroleum Companies and not from the Retain Network.

- New, modern equipment on-site.

- Better fuel quality, resulting in lower maintenance costs for your vehicles.

- Constant consumption monitoring and reporting per vehicle / group of vehicles.

- Less administrtive costs, since you do not have multiple refuelling invoices per vehicle to check and register.

- Full control on the fuel quantities received and constant stock monitoring.

- Fully controlled, automated refilling process for all drivers / vehicles. No site attendant needed, since pump is electronically controlled (locked) and authorized only by card / tag / ring.

- User-friendly Backoffice Managerial Software that can be further connected to Accounting Software or ERP Systems.

Spyrides Group provides a Turn-Key Solution for your company's Internal (Industrial) Refilling Site, including Construction Works, State-of-Art Equipment and Software, Users' Training and Pilot Operation.

We have already delivered numerous Internal Refilling Sites Projects for various of our customers, like:

- Transportation Companies

- 3rd Party Logistics Providers (distribution vehicles, forklifts, sales force vehicles etc.)

- Super Markets

- Security Companies

- Industrial Companies with distribution fleet, sales force fleet etc.

- Construction Companies (Construction works equipment)

- Quaries

- Public Sector (Police, Municipalities, Post Office, Fire Department, Public Buses Companies, Utilities Sector Providers etc.)

- Marine Filling Stations etc.

- B2B Solutions

- Download File

LPG STATIONS

Spyrides Group S.A provides a Turn-Key Solution including both equipment and construction works for Auto Gas–LPG stations.

All our Engineers and Technicians are well-trained, qualified and experienced to offer you the best services, using reliable and technologically advanced European parts and equipment.

- LPG

- Download file

CERTIFIED TECHNICIANS

Our welders are certified according to ELOT ΕΝ 287-1, from an independent certification body, while all weldings follow ELOT ΕΝ 288-2 standards.

All equipment and parts used is from high-profile European suppliers, according to international standards (UKLPG) and tested in European countries where Auto Gas-LPG has a long history.

Design always based on safety rules and procedures, ensuring reliability and continuous operation, providing the most suitable technical solution in the most competitive price.

The use of a series of pneumatic safety valves, manually operated valves, pressure relief valves and regulating valves, ensure safe and continuous operation under all types of weather conditions, and for many years.

Our M-5200 LPG Dispensers are certified according to ΑΤΕΧ 2014/34/EU and comply with European Standard EN14678-1. They are also certified according to MID 2014/32/EU, providing the most suitable and reliable solution for LPG dispensing.

LPG PIPES & EQUIPMENT

For pipeworks we use seamless carbon steel pipes with high-pressure fittings, specified according to ANSI B36 10 API 5L GRADE B SCH 80.

Steel valves "Ball Valve Type" according to PN40.

High quality pneumatic safety valves, with motors specified according to international standards.

Installations are tested with radiographic tests for a 10% for all above ground networks and 100% for underground networks. Furthermore, all installations are tested with Hydraulic and Air-Pressure tests.

Upon Project conclusion, a full technical file with all relevant certificates for equipment and works is delivered to the Customer.

A further advantage is the continouus presence of our technicians to your stations all over Greece, sinceh our premises in Athens, Thessaloniki, Heraklion, Larissa and Patras enable us to provide you the highest quality maintenance services for LPG stations, in the fastest response times.

LPG Equipment

LPG Dispenser

Our Μ5200 LPG Dispenser is a high quality product, following all European Norms and Standards.

Metal parts from galvanized steel, powder coated, suitable for operation in harsh enviromnents. With filter, air eliminator, flow meter, differential valve and all other safety valves to ensure safe operation and easy maintenance.

High accuracy positive displacement flow meter, made of malleable cast iron.

• Accuracy: +/-0,6% • Inlet thread: 1" BSPP • Outlet thread: NPT

Cutting edge electronics, with big Blue back-light LCD displays, with preset keypad and safety Pulser.

Open communication by using IFSF protocol (International Forecourt Standards Forum) enabling connection to any POS System or Forecourt Control System (such as Station Guard etc.)

Equipped with Emergency Stop Button, to immediately stop LPG's flow and shut down the equipment. Presence Button to ensure an authorized person is attanding refuelling process.

Hose resistant to 90 bar rupture, according to international standards, equipped with safety break-away valve.

Nozzle and safety break-away valve of the highest quality, from well-established international manufacturers like OPW, Rego & Nettuno.

Available with 1 or 2 nozzles.

Technical Characteristics

M-5200 LPG Dispenser is available with 1 or 2 nozzles | |

| Flow Rate | Min: 5lpm / Max: 25lpm |

| Working Pressure | 9 - 11 bar |

| Max. Working Pressure | 18 bar |

| Dimensions | 930mm x 510mm x 1650mm height |

LPG Equipment

LPG Tanks

Available in various capacities, with all safety accessories according to international standards: 4 excess flow valves, back-pressure valve, 2 pressure relief valves & CD35, Level Gauge Rochester 0-100%, Duo Port safety valve, Level Gauge 85%, Calibrated dipstick, Casing pipe & with flange for 15% - 85%.

Optional installation of LPG tank gauging probe of any manufacturer, in a special probe case.

Certified according to 97/23/EC (PED) Directive.

LPG Pump

Centrifugal (multistage) surface pump, with ATEX approved motor, with By-Pass valve and vapor eliminator. Available in many types.

Certified according to 2014/34/EU ATEX Directive.

Submersible LPG Pump

Multistage submersible pump, quit operation, for applications that increased flow rates are required. Equipped with internal By-Pass valve for continual cooling. Available in 2 types for 70 lpm & 100 lpm, depending on the application.

Certified according to 2014/34/EU ATEX Directive.

Piping network from steel pipes of SCH 80 type exclusively, for maximum safety. Installation designed for maximum pump efficiency and highest safety.

Network equipped with Pneumatic Ball Valves PN40, manually operated Ball Valves PN40, safety valves in critical network points, enabling continuous operation and immediate LPG fuel shut-off in case of emergency. Installation of Gas Sensors and Fire Protection System, for immediate leak detection.

AVETEL S.A, member of SPYRIDES GROUP, is a dynamicaly developing company active in the field of advertising structures, having as purpose the implementation of corporate identity projects. Having delivered numerous projects for Petroleum Companies, which include design and installation, AVETEL S.A is rcognized not only as a key player for Petrol Stations' Signage and Canopies, but also as a major supplier for any Retail Network.

With vast experience and know-how, state of the art manufacturing equipment and executives of the highest profile in the indusrty, AVETEL S.A provides turn-key solutions for both internal and external signage, for any Retail Network, and with the well know SPYRIDES' GROUP reliability and consistency.

Customers of AVETEL S.A are well-know Petroleum Companies such as AVIN, CYCLON, ELINOIL, ARGO, SHELL etc, as well as Retail Networks like ΤΟΥΟΤΑ, LIDL, SARAKAKIS GROUP, FORD, SKLAVENITIS, VEROPOULOS, VODAFONE, VIVARTIA GROUP (GOODY’S – FLOCAFE).

For more information, please visit www.avetel.gr

- Avetel

- Download file

Dem. G. Spyrides S.A offers a wide range of solutions for:

- Tank truck equiment

- Heating Oil Depot equipment

For any Heating Oil Depot, we offer the following main products:

- Pumping Skids, ATEX certified (pump & meter)

- MC Positive Displacement Flow Meters, highly accurate and reliable, ΑΤΕΧ certified, for flow ranges 200 to 3000 lpm. Standard versions include strainer, air eliminator and Veeder Root Mechanical Register, optional available witl preset, printer, Electronic Register, connection with Fiscal System (console)

- Silea Top or Bottom Loading arms, 3" or 4"

We also provide additional equipment for tank trucks - depots such as:

- Pumps for tank trucks (coupled to the truck's transmission box)

- Pumps coupled with gasoline engines

- 12/24V – ATEX certified pumps

- Pipes

- Reels

- Nozzles